With the wide application of solar energy devices in different climate regions, the reliability of rapid shutdown equipment in extreme weather has become a key focus in the shutdown industry. To ensure the stable operation of photovoltaic systems in harsh environments, designing a robust protection strategy is crucial for maintaining compliance and safety functions.

Weather vs. Electronics

With the wide application of photovoltaic systems in extreme climate regions such as strong ultraviolet rays, high humidity, snowstorms and thunderstorms, environmental pressure is affecting the integrity of the RSD’s casing, wiring and connectors.

To solve this problem, waterproof design alone is not enough. Comprehensive control from design, testing, material selection to production is necessary to guarantee product reliability.

Key Strategies to Ensure RSD Reliability in Harsh Environments

1. Robust Enclosure Design and Protection Ratings

One of the most critical aspects of ensuring reliability in unpredictable climates, is choosing an RSD with a high protection rating. Devices with IP66 or IP68 protection can resist water ingress, dust, and corrosion—even during torrential rain or desert sandstorms.

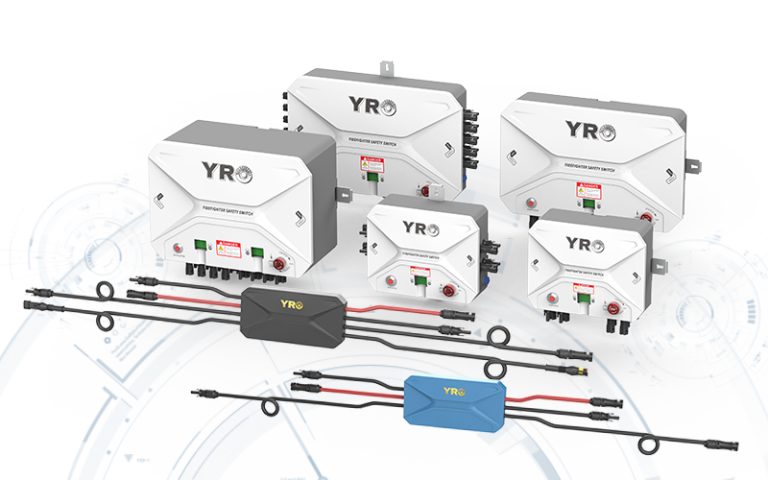

YRO’s rapid shutdown devices use UV-resistant, flame-retardant polymer enclosures treated with anti-aging processes, maintaining appearance and performance stability even in high-UV regions like Southeast Asia and the Middle East.

2. Thermal Stability Under Temperature Differences Throughout the Four Seasons

In environments with large temperature differences between day and night (such as deserts and mountains), materials are prone to fatigue due to thermal expansion and contraction, and the connection points are also likely to become loose. Therefore, high-quality RSD must have the ability to operate at wide temperatures and usually needs to withstand extreme temperatures ranging from -30°C to +60°C.

Such products utilize electronic components resistant to extreme temperatures and silicone-sealed terminals to ensure stable operation under harsh climate conditions.

Strict Testing and Quality Control Procedures

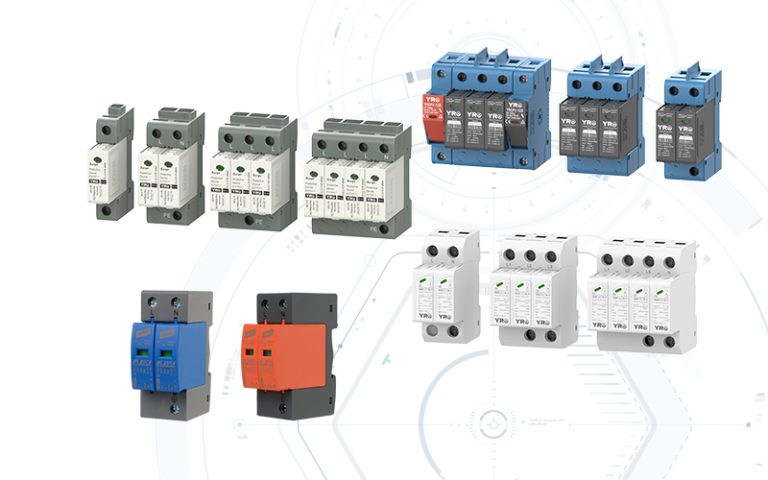

Whether equipment can operate reliably long-term depends on the manufacturer’s quality control. Reputable firefighter safety switch manufacturers conduct the following tests:

- Salt spray corrosion testing

- UV aging simulation

- High and low temperature thermal shock testing

- Structural compression testing

All YRO RSD devices undergo 100% functional testing before leaving the factory, simulating real-world operating conditions.

Will the Rapid Shutdown Function Trigger Accidentally on Cloudy Days or Under Low-Light Conditions?

One of the most frequently asked questions by users is: Will the rapid shutdown switch be mistakenly triggered in weak lighting conditions? In fact, when the voltage of the photovoltaic panels is insufficient, the rapid shutdown will be in standby mode.

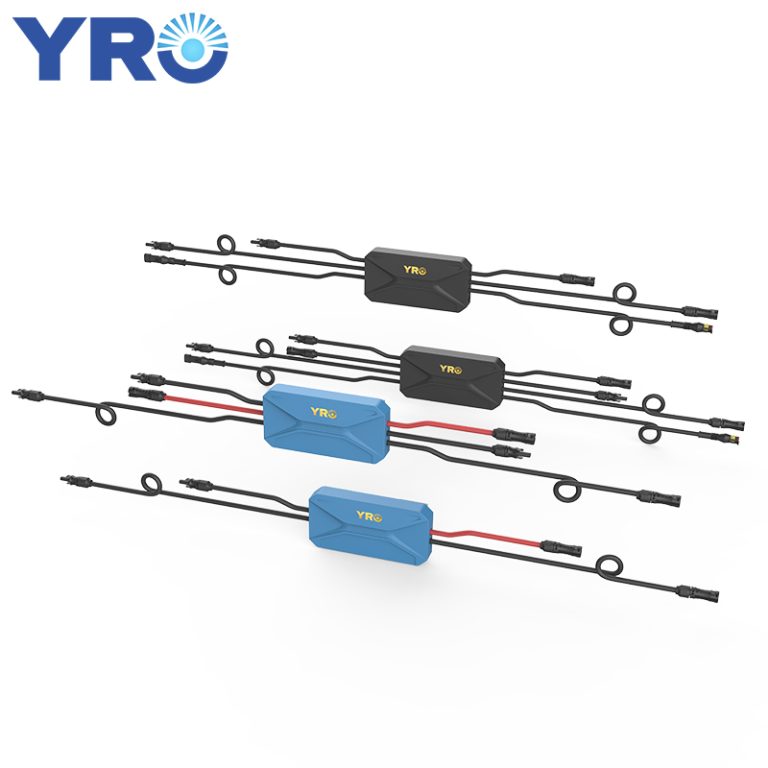

YRO’s module-level shutdown operates at 12V, while string-level shutdown operates at 220V. They only function normally when the voltage exceeds their respective operating thresholds.

Conclusion

Against the backdrop of the accelerated global deployment of solar energy, safety equipment capable of withstanding extreme climates, has been upgraded from a compliance requirement to a core element for ensuring investment returns, personnel safety, and the long-term reliable operation of systems.

Choosing a manufacturer like YRO that pays attention to weather resistance, has CE and UL certifications, and has practical application experience is a truly strategic choice.

Looking for an RSD solution adaptable to diverse climates? Contact us to learn more about YRO’s rapid shutdown products and support your project’s long-term success.