In power systems, fuses are safety protection products. When an abnormality occurs in the circuit, the fuse will protect other devices by melting itself. But many people would ask: Can a fuse be left in its original place without being replaced after it burns out? In fact, doing so may pose safety risks.

Hidden Dangers of Leaving a Blown Fuse

- Masking potential electrical problems: The blowing of the fuse link is usually caused by circuit overload, short circuit, or other electrical faults. If the blown fuse link is not replaced in time, these underlying issues may go undetected. When the circuit fails again, it can easily cause equipment overheating, insulation damage, or fire.

- False sense of security: A blown fuse may create a false sense of security. Although it has cut off the current, the terminals on the power supply side still carry normal operating voltage. For personnel troubleshooting the power outage or preparing to replace the fuse, if necessary safety precautions are not taken, there may be a risk of electric shock.

When Should the Blown Fuse Link Be Replaced Immediately?

If any of the following situations occur, the blown fuse core should be replaced immediately and professional electricians should be involved:

- If the circuit breaker trips repeatedly after replacing the fuse, it indicates that there is a potential electrical fault

- Visible signs of electrical damage such as burning, melting or discoloration

- Multiple fuses burning out in the system within a short period of time indicate that there is a more serious circuit problem

How to Repair a Blown Fuse Link?

First, state the point clearly: A blown fuse link cannot be repaired! It must be replaced with a new fuse element of the same specifications.

Replacing a fuse element is actually not complicated, but it needs to be done according to standard procedures to ensure safety. Please follow the basic process below:

Step 1: Power Off Confirmation

Disconnect the power supply from the upper level and verify that there is no electricity using compliant measuring tools. When operating, wear personal protective equipment as needed, including insulating gloves and goggles.

Step 2: Identify the Cause of the Blow

Just replacing without finding the cause often leads to another blow. Check for short circuits, overloads, poor contact resistance due to loose wiring, high ambient temperature rise, abnormal harmonic/inrush current, etc.

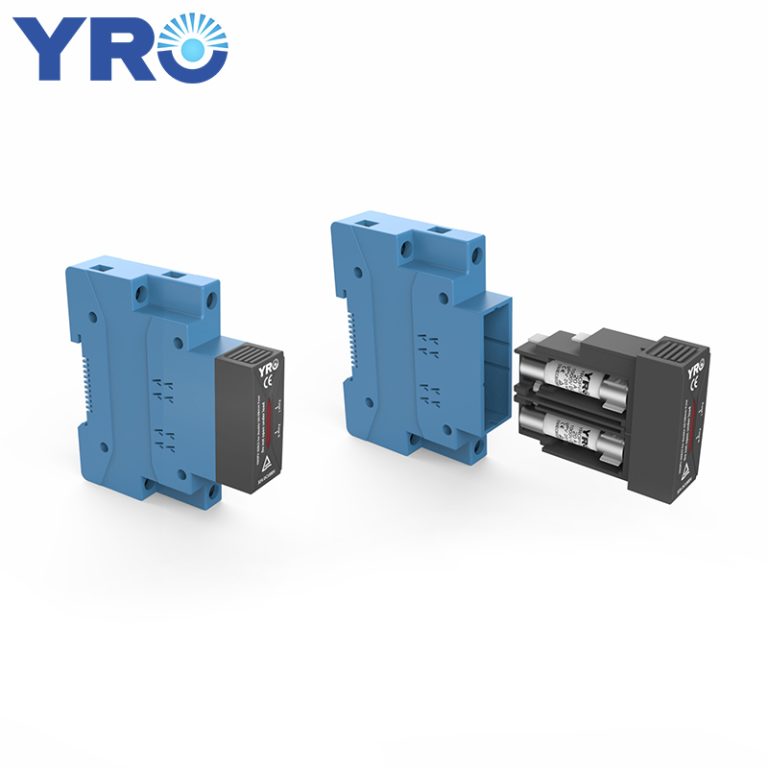

Step 3: Select a Suitable Replacement

- Keep the rated current and voltage levels the same

- The breaking capacity must meet the fault current requirements

- The fast and slow melting characteristics should be consistent with the original model

- Give priority to using products that are compatible with the equipment/cabinet manufacturer and certified.

Step 4: Inspect and Handle the Fuse Base

Check for signs of discoloration, scorching, or deformation. Clean the contacts, replace damaged bases or terminals promptly, and tighten to the specified torque.

Step 5: Installation and Reset

Install the new fuse link/the entire fuse as per the instructions to ensure good contact. Check the circuit and load status again before closing the switch.

Step 6: Power On

Gradually restore power supply and observe the changes in operating current and temperature. If conditions permit, an infrared thermometer can be used to check the temperature at the connection points. Finally, record the fault situation and the handling measures.

Safety Always Comes First

Keeping a blown fuse poses unnecessary risks to property and personal safety. In contrast, the time and economic cost required for the correct replacement of fuses are far lower than the possible consequences of ignoring this issue.

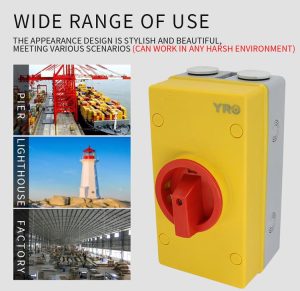

Electrical safety depends on key details. Regular inspections, standardized operations and reasonable load arrangements can help extend the service life of power equipment and reduce the occurrence of fuses burning out.

Please pay attention to the situation where the fuse blows. Replace it in time when necessary to ensure that the power system is effectively protected.